As new decorative and structural finishes become available, Righetti’s R&D Department is constantly tasked with new projects, with the aim of providing lifting systems adapted to the new requirements. Recently, we received requests to provide the appropriate lifting mean for a peculiar type of sandwich panels, and our R&D Department worked hard to develop the perfect solution.

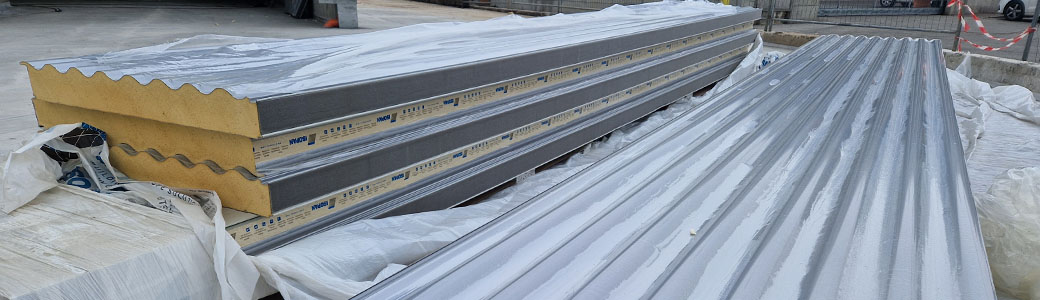

A couple of customers, frequent users of our vacuum lifters for insulated panels, came to us with a unique requirement: they asked us for a solution for lifting and subsequently installing wavy insulated wall panels horizontally. One request was for handling ‘Isoclass’ panels produced by the company Isopan, the other request was for installing ‘Onda’ panels by Isolpack.

Both panels differ from the others because of their surface, which is characterised by a wavy finish. This peculiarity gives an attractive appearance, but poses problems for the handling of the load itself. In fact, from the very first analysis, it was clear that the soft curves of the profile did not allow for the adherence of neither the standard suction pads, which our vacuum lifters mount as standard, nor other types of pads designed up to that time, which were instead suitable for lifting wavy roofing panels. On the contrary, they required the development of ad hoc suction pads.

Thanks to the technical support of the manufacturer Isopan and the panel samples provided by Isolpack, we studied and designed a solution that could adapt to the peculiar external profile of wavy sandwich panels, both Isoclass and Onda.

After careful design, the experience of our R&D Department enabled us to provide our customers with the ideal solution to their needs. We developed suction pads with a specific shape and a special shaped gasket that could perfectly adhere to the smooth outline of the panel.

The suction pads developed can be repositioned along the arms in order to optimise load balancing; they are also positioned crosswise and opposite each other to respect the balance of the dual vacuum circuit, which the vacuum lifter is equipped with in compliance with EN13155.

The specific suction pads for wavy panels are applicable on our CL1-series panel vacuum lifters. As a result, our customers can count on a number of features that come as standard on these models: rechargeable battery power for unrestricted operation; a powerful vacuum system for immediate suction; a smart control unit to ensure high levels of safety; and a robust, modular frame to handle any panel with ease.

Let us know your needs and we will guide you in the right direction.

Visit our page, select and fill in the information according to your requests.